Well, it was time to drag it back out and take a good look at it and start cleaning.

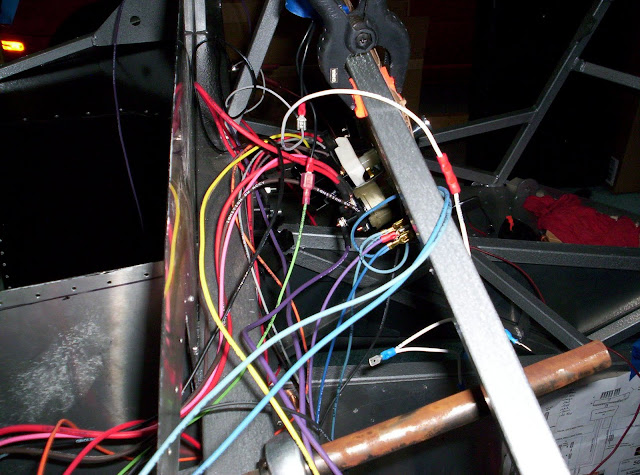

I'd forgotten how bad it looked...

(Oh, click on the pictures for full size. I don't know why the previews are always cut off here, but they are.)

Pretty bad actually. And take a look at the motor mounts.

They're in great shape, eh?

Luckily I have a set of Energy Suspension poly mounts to replace those once everything gets cleaned and pretty again.

Since I can't put in something that ugly, I decided to do something about it. I spent some time on the internet and a few days later I got home to find this waiting on my porch.

Now what could be in those boxes? Hmmm. You'll have to wait to find out.

My wife has been promising to help me with this project all along but she really doesn't enjoy mechanical work. Despite that she helped me pull the engine and transmission a while back.

But what she does enjoy is bodywork. So we pulled the body shell off of the tall storage body buck and got it to working level for her. Then she went to work sanding the gelcoat seams. They're going to take some work to get completely cleaned out and ready for HSRF but not nearly as bad as others of which I've seen pictures.

After that it started raining. Of course...

If you look closely behind her, you'll see her project car that gets started when we finish the Roadster. It's a 1965 Rambler Marlin with a fire-breathing 232 CID straight six engine and automatic transmission.

Here's a picture of the car from the ad where we bought it.